Andrea is a client who built a custom double sink bathroom vanity. Andreas vanity has drawers and doors and then there are two storage tower cabinets that sit on top of the vanity for even more storage. This is part 1 of her project story.

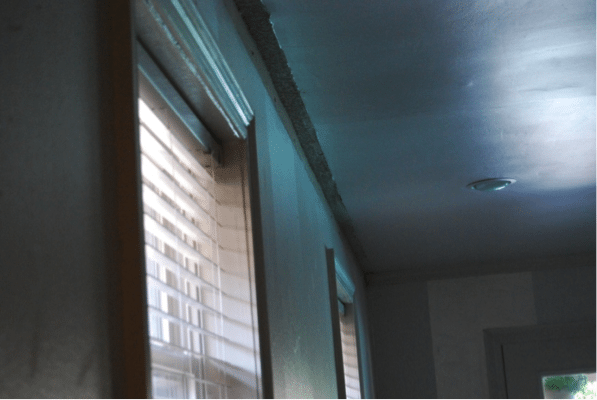

Andrea’s Bathroom — BEFORE

This building thing has been an education in patience and self-discovery. Patience with myself (I like to be perfect, but that is not a possible factor in building), discovering my own “creative process” (which is just a lot of thinking and planning + procrastination + feeling defeated a lot + needing a break to get over my defeat after every. single. step.), and learning to deal with the unexpected.

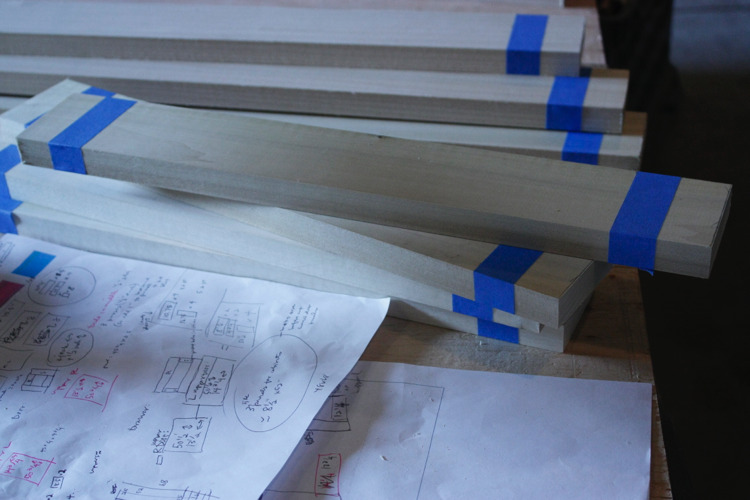

I received my instructions, bought the wood (the same day – man, this was going to be done in no time! – I thought), and then wondered how I would cut it. My husband wouldn’t let me use his table saw because he said it would, and I quote, “tear off your arms and legs.” Yeah. It is old and scary – crooked without a fence. So we hunted for a table saw. Which took a month.

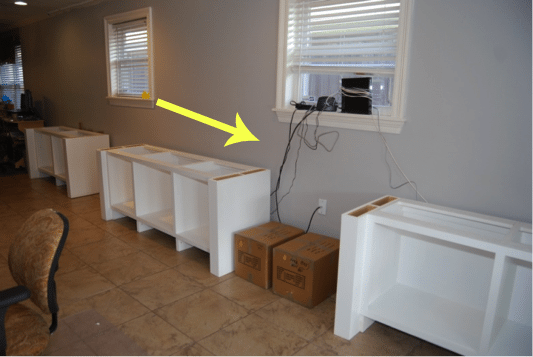

I built my carcasses after thinking about it and being too scared to do it for a couple weeks.

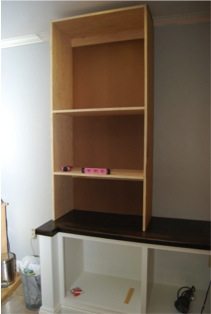

It was so exciting to get them done, I texted pictures to my husband. He immediately asked if they were square. So I held my breath and measured. Then I sent this picture to him. Because they WERE square, and I felt so relieved I could have kissed them. (but I settled for a quick hug).

Then they sat in my garage for a month. Then they sat in my basement longer. I needed straight wood for my face frames, but none was to be found. Anywhere.

Christmas came and went. December was a complete bust. Except for the tool pouch my husband gave me for Christmas– stuffed full of my favorite mint chocolate truffles and a tape measure of my very own. People looked at me funny when I answered their, “What did you get for Christmas?” with that.

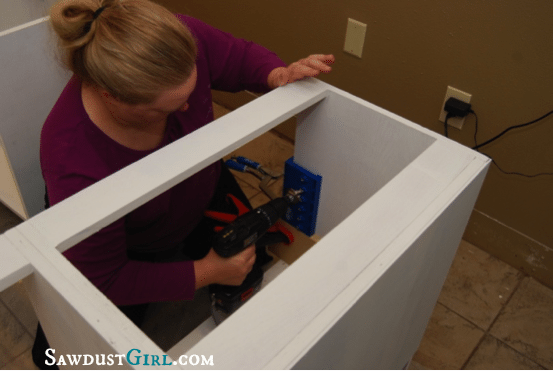

I got my husband to help me install the carcasses, cause those puppies are heavy and awkward, and I didn’t know how on earth to do it. We added beadboard to the exposed side with some liquid nails, and we clamped that down and let it dry. It made the whole basement stink. I’m pretty sure liquid nails kills brain cells. But what are a few brain cells when it comes right down to it?

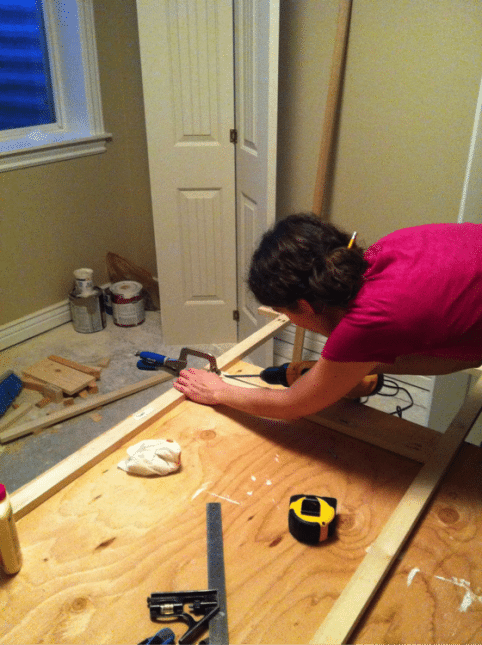

I finally just decided to make do and cut straight pieces of wood out of really long boards, and had my face frame done in no time. Why had I waited so long? It was a cinch with my awesome pocket hole jig (I had to get a feel for it first by building an end table with about 40 bajillion pocket holes in it – that took a couple hours, but then I felt confident in my pocket-holing abilities).

(Oh, did I mention I was painting and caulking every square inch of my basement in between all this? Yeah, it was a very un-fun winter at our house)

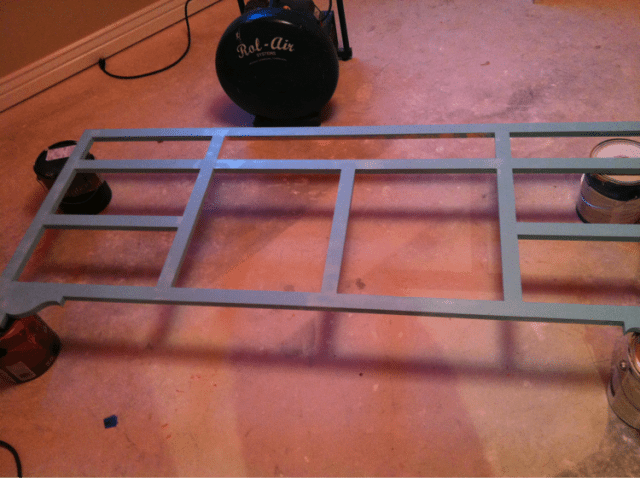

Anyway, I sanded and painted the face frame (two coats of primer, two coats of turquoise),

and it took me at least a week to work up the courage to install it. Then I patched the nail holes and repainted it. It looked so beautiful. Every completed stage is like heavenly shafts of light beaming down and angel choruses – the project looks so much better!

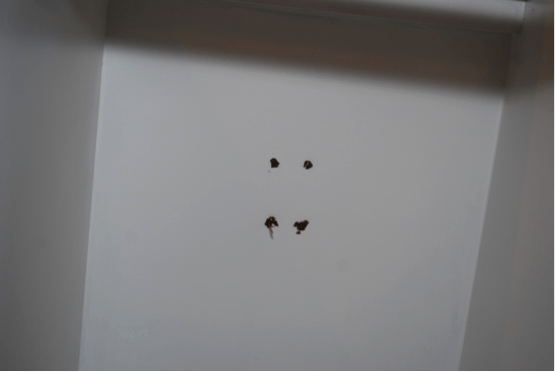

(never mind the little mints in the photo – I took the picture for my friend who knew I was feeling overwhelmed, and suggested I lure someone into the bathroom to finish my project for me…it didn’t work, just in case you wondered.)

I built my upper carcasses, but had to wait for counter tops before I could finish them. In the mean time, carpet was installed downstairs, so I lost my workspace. The weather was nasty (as it is 8 months out of the year here), so it got REALLY hard for me to find the will to work on my project. I am not much (at all) for being cold and/or uncomfortable.

Like every phase of this project, the countertop phase was a one step forward, two steps back experience. It took a month for the counters to be poured and ready (after much debate, we settled on decorative concrete). Then it cracked in half on the way to deliver it to my house. They had to start over. Then they installed the sink, and we discovered that the drain (which we had never thought to look at) was way too high. We tried to find a plumber willing to move it (so we wouldn’t have to buy a new sink and faucet or rip out the cabinets), which took some time. Then the holes in our brand new sheetrock that resulted were daunting and frustrating. Like, you guessed it, everything else. To which lead me to share my inner monologue with you via a daily journal so you can accompany me on the duration of this journey.